The demand for modular infrastructure in Zambia’s mining sector is currently growing rapidly as the industry expands to meet global copper demand. With copper prices remaining at very favourable levels, nearly all mines in the region are undergoing significant expansion projects.

Mining continues to be the cornerstone of Zambia’s economy, contributing over 20% of the country’s Gross Domestic Product (GDP) and accounting for more than 70% of its export earnings. As the sector scales up to meet surging global demand for copper and fuel national development, the imperative for fast, efficient and adaptable infrastructure in remote, high-intensity mining environments has never been more critical.

Modular solutions for a dynamic mining sector

Karen Olivier, Business Manager at Waco Modular, says the current growth in the mining sector has created a heightened demand for modular infrastructure, which, for this application, is far more suitable than traditional brick-and-mortar structures.

“Most of these sites are open-pit operations, and their nature requires a flexible approach to infrastructure. A great example is Kansanshi’s expansion; as the current pit reaches depletion, they’re shifting mining activities to a new area,” she says.

“This transition requires the removal of all existing buildings around the current site. With brick-and-mortar, that would mean demolishing and hauling away debris. With modular buildings, they can simply relocate with ease.”

Speed, flexibility and scalable solutions for mining sites

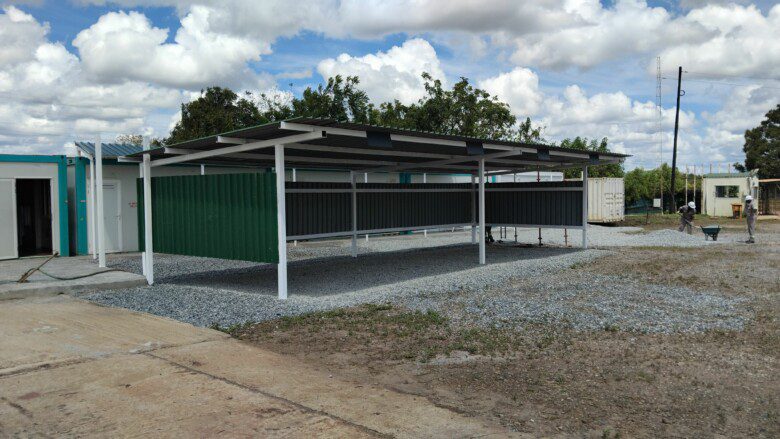

Relocatable modular infrastructure appeals to mines for its agility and adaptability. Waco Modular’s solutions provide the flexibility and speed unmatched by traditional brick-and-mortar.

“What sets Waco Modular apart is our ability to deliver at speed. From the moment an order is placed, we can complete and deploy a fully functional building within days – a stark contrast to the months required for traditional brick-and-mortar construction, which involves extensive site preparation and on-site activity,” says Olivier.

“Our prefabrication method allows most work to be done off-site in controlled conditions, minimising disruptions, reducing safety risks, and ensuring smooth integration into high-security environments for our teams and clients.”

Modular designs are scalable, allowing for rapid assembly of customised multi-unit structures. Their flexibility makes them ideal for dynamic, high-pressure mining environments where operational requirements can shift quickly.

Robert Henderson, Branch Manager at Waco Modular in Zambia, notes that mining projects often face unpredictable timelines and delays. Once decisions are made, companies expect quick mobilisation, especially in remote locations with minimal infrastructure.

“Waco Modular excels in off-site manufacturing and assembly, significantly reducing deployment times and on-site disruption. Although, depending on the size of the project, we can deliver fully functional buildings within days, allowing clients to maintain operations without delays. Our fast, safe, and scalable solutions are perfect for the harsh conditions of the mining environment.”

Henderson also highlights the increasing demand for various purpose-built modular units, including a recent custom-designed blasting observation auditorium with a full glass façade, enabling safe real-time monitoring of blasting operations.

“We’re also finalising a change house for miners to have a clean, secure space to change and shower after shifts, boosting hygiene, safety and morale on-site,” he says.

Engineered for Zambia’s demanding mining conditions

Purpose-built for Zambia’s demanding mining environments. “Our solutions use robust materials and modular flexibility for durability and easy maintenance. Each unit is engineered to perform in extreme conditions, ensuring mobility and resilience as operational demands and infrastructure evolve.”

As Zambia’s mining sector continues to expand, the demand for rapid, flexible and sustainable infrastructure is becoming increasingly urgent. Waco Modular is rising to meet this challenge through continuous innovation and agile design, ensuring its modular solutions evolve in step with the industry’s shifting needs.